I love taking things apart and fishing for spare / rare parts… in doing that, I’ve seen a lot of different PCB finishes and what time does to them.

Copper is a critical element in hardware design; yet it’s sensitive to oxygen, moisture, temperature, and pollution – a protective finish is the key to longevity.

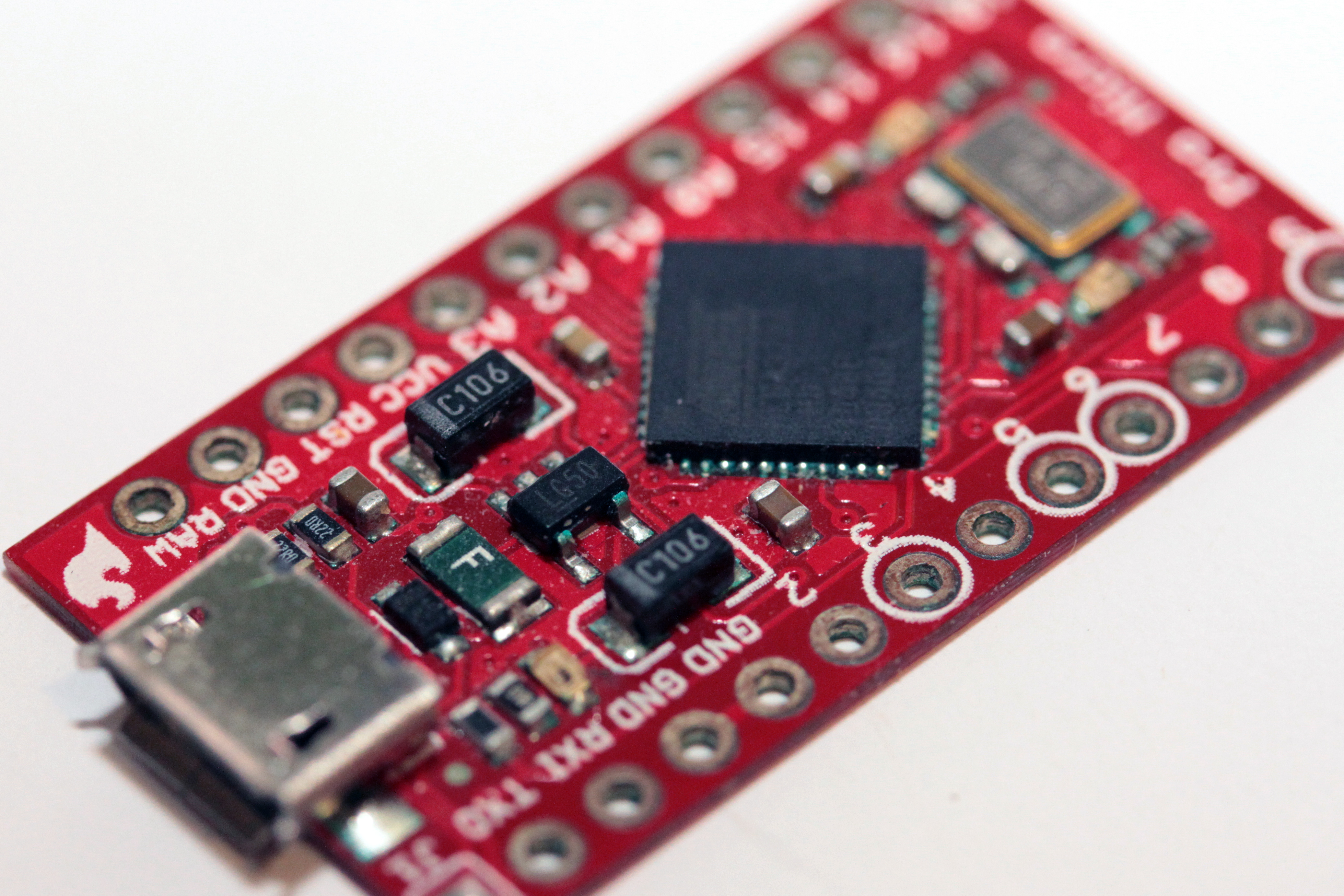

As you can tell from the image above, leaving even a little bit of bare copper exposed to the elements can be bad news. Yuck!

Here are two alternatives.

Hot Air Solder Leveling (HASL) boards are dipped in molten solder and then the excess is ‘spritzed’ off with hot-air knives, leaving a thin layer of solder behind to protect the traces from corrosion. People often choose this finish because it’s inexpensive and fairly easy to solder large components to. On the down-side, smaller / surface mount components don’t always sit flat, due to excess solder collecting at the edges of a trace. These ‘bulges’ can have an appreciable effect on heat absorption… causing molten solder to pull a component straight up (a.k.a. tombstoning) with its newly found surface tension. Not a deal-breaker, but something to keep in mind.

Un-used boards can be stored in a baggie with an oxygen absorber to keep them ‘fresh’ a little longer; vacuum seal if you can. HASL isn’t a bad option, but it’s not the best.

If you can spare the extra pennies, I would definitely recommend Electroless Nickel Immersion Gold (ENIG). The gold layer is thin, very thin, and isn’t intended to provide any appreciable structure to the trace – it’s merely a protective coating. Enough to prevent tarnish, corrosion from the oil on your fingers, etc.

If you can spare the extra pennies, I would definitely recommend Electroless Nickel Immersion Gold (ENIG). The gold layer is thin, very thin, and isn’t intended to provide any appreciable structure to the trace – it’s merely a protective coating. Enough to prevent tarnish, corrosion from the oil on your fingers, etc. ENIG traces are flat, square, are friendly to microscopic components… and it has an impressive shelf life. This little guy (right), should last a generation or two.

[ EOL ]